Extremely fast and precise

Milling-

machines

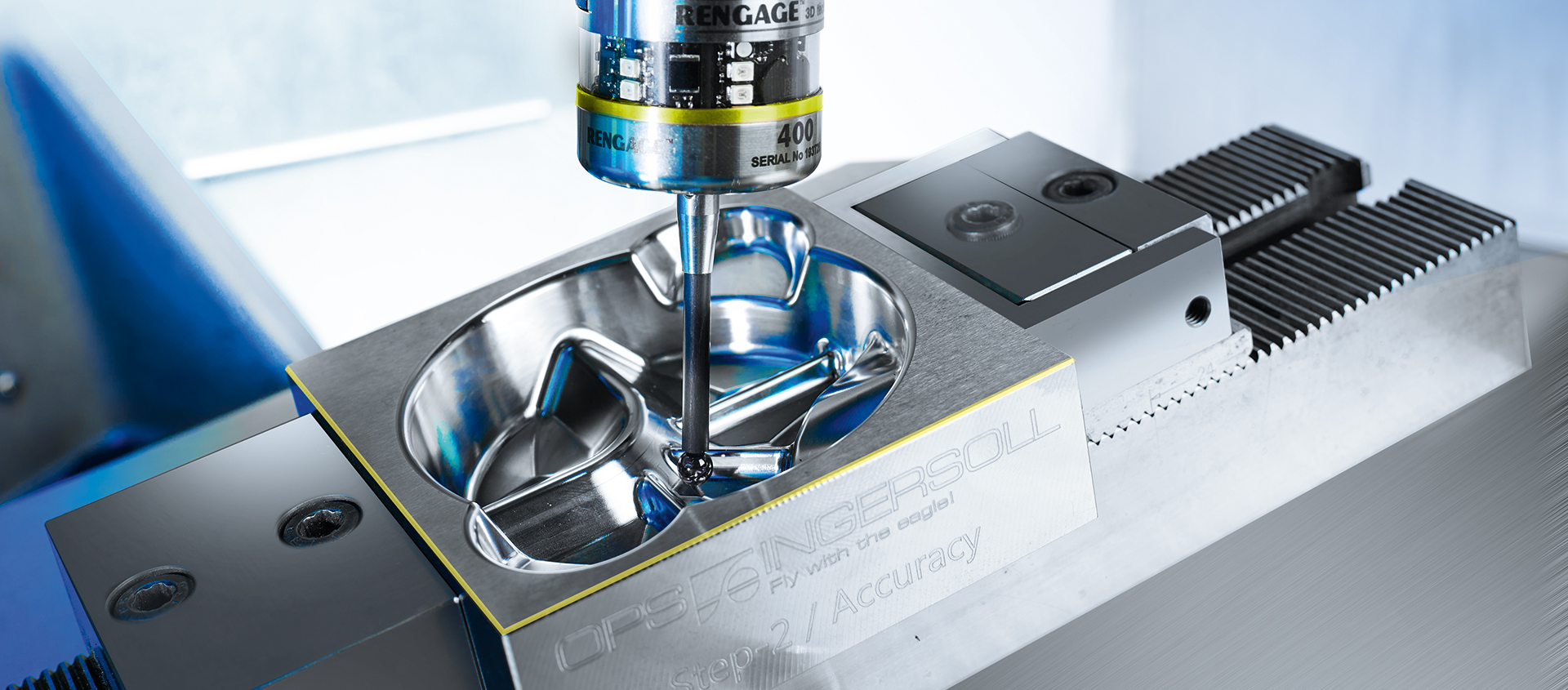

High-speed milling: The key technology in tool and mold making. With our HIGH SPEED EAGLE series, we offer highly dynamic machines with "Made in Germany" quality. By consequent further development of our technology, the HIGH SPEED EAGLE machines increase your flexibility and productivity, reduce downtimes and guarantee outstanding process reliability.

Convince yourself of our technological lead:

- Maximum precision and surface quality in minimum tolerance range

- Multi-material technology for processing graphite, copper and other special materials

- Variable multi-axis machining thanks to gantry portal design

Cutting of ambitious geometries in hardest materials

Multi-axis machining

With our HIGH SPEED EAGLE V-Line machining centers, you are ideally positioned in terms of precision, speed and cost-effectiveness. The milling machines offer numerous variants of simultaneous multi-axis machining to produce complex geometries, curved surfaces and sophisticated contours in just one clamping operation. Optimized for your application, special processes such as shaft machining can also be implemented with our all-rounders.

Our pioneering technology solutionsMilling machines

Travel distances, Table load, Multi-axis machining: Find the right milling machine for your high-speed milling applications from our HIGH SPEED EAGLE V-Line model series. From the entry-level model V550 to the high-end solution V9, we cover the entire machining spectrum of highly dynamic milling.

HIGH SPEED EAGLE V550

3-axis

max. 500 kg

5-axis

max. 250 kg

- Entry into precision milling

- Integrated tool changer 32 position

- HEIDENHAIN-Control TNC 640

HIGH SPEED EAGLE V5

3-axis

max. 500 kg

5-axis

max. 250 kg

- Integrated tool changer 32 position

- Flexible automation solutions possible, also as retrofit

- HEIDENHAIN-Control TNC 640

HIGH SPEED EAGLE V9

3-axis

max. 2.000 kg

5-axis

max. 500 kg

- Maximum dynamics thanks to double gantry drive

- Integrated tool changer up to 88 positions

- HEIDENHAIN-Control TNC 640

More possibilities and precisely working!

HIGH SPEED EAGLE

Competition Line

High performer for flexible use

Our Competition-Line machines convince with their flexible equipment possibilities. Due to the vibration-damped polymer concrete bed, the capsuled design and laser-supported sensor technology, the Competition-Line allows highly dynamic milling of graphite, steel or non-ferrous metals, both in dry and wet machining.

HIGH SPEED EAGLE

Precision Line

The upper class for top precision

Economical and reliable milling with absolute precision in the minimum tolerance range, with the best surfaces and the highest repeatability: this is what you can achieve with our newly developed Precision-Line milling machines for machining precision parts. 5-axis simultaneous machining with a precision of less than 10 µm during active temperature control of all drive components.

Young used machines from OPS-INGERSOLL

Proven quality from OPS-INGERSOLL is also available second-hand.

The used machines are overhauled by our technology experts and offered with a factory warranty. As the manufacturer of the machines, we offer competent in-house training for these machines. Would you like to convince yourself of the durability, reliability and long-lasting precision of our machines? Then give our used machines a second life.