Business sectors

Solutions for ambitious industrial sectors

Solutions for ambitious industrial sectors

Industry requirements

We are a leading partner for international tool and mould making. We have two main technologies and end-to-end automation solutions. Furthermore, over many years we have acquired outstanding know-how for the requirements of our partners, which makes us to a technology partner for the entire process chain in tool and mold making.

Special solutions

Our machines are uncompromisingly designed to meet the special requirements of tool and mould making, and our automation solutions are practice-oriented and reliable. They can often be used economically from batch size 1.

Industry requirements

The automotive industry is constantly demanding lower prices from its suppliers and at the same time shorter delivery times. But a consistently high quality is nevertheless a requirement. The combination of high speed milling and spark erosion often enables our customers to achieve considerable increases in productivity. Following a detailed analysis, we will be happy to show you an individual solution concept and point out your advantages with a profitability calculation (before/after).

Special solutions

We have automation solutions that combine different machines and technologies. However, smaller automation units are often the most economical solution, depending on the specific requirements of the individual customer.

Integrated job management systems, for example from our cooperation partner EVOMECS, enable you to supervise and control your process, so that you can react flexibly to changing requirements.

Industry requirements

Medical technology requires the highest demands on accuracy and surface quality. The tools often have a high number of cavities, but at the same time a high degree of automation is required.

With the EAGLE PowerSPARK generators, a surface quality can be achieved with graphite, that was previously not possible and is unique in the world. In addition, all our machines feature unique copper technology. Outstanding mechanical engineering and ingenious cooling concepts ensure the special requirements of this industry and can also be achieved by the technology combination.

Special solutions

With our EAGLE G5 Precision, we have an innovative machine concept for maximum precision. This machine guarantees accuracies of less than 5 µm on the part. With our PowerSPARK erosion technology, surface classes up to VDI 7 with graphite are possible. Our special multi-cavity technology reduces electrode wear by up to 50% while at the same time reducing machining times. Our precision high speed milling machines guarantee accuracy in electrode production and hard milling. This ensures maximum accuracy, especially in the technology combination.

Industry requirements

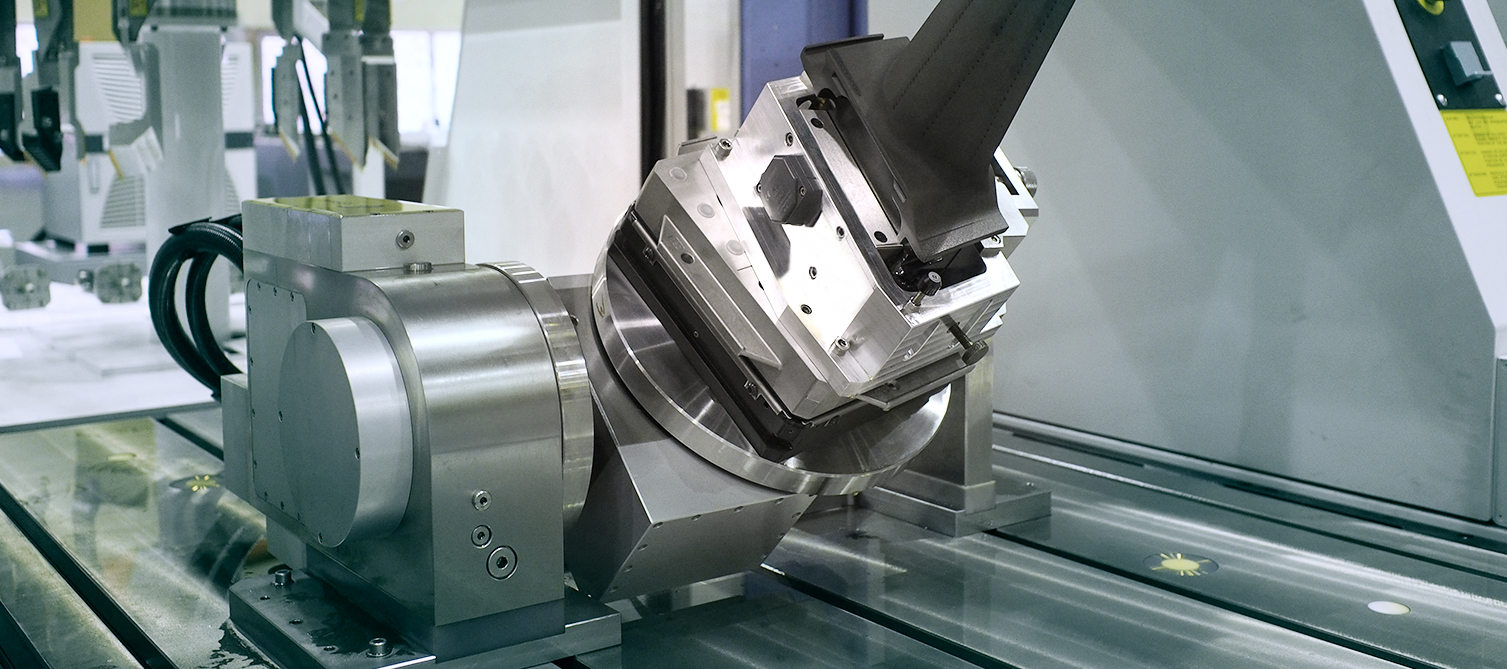

In addition to international tool and mould making, the businees sector of energy production is an important branch of our business. Our specialties include the machining of special materials, such as inconel and specific motion guides for multi-axis simultaneous erosion.

Special solutions

Our gantry machine concept is an excellent basis for special machining tasks. Despite long travel distances there is still easy access to the workpieces possible. We have solutions with 6 or more eroding-axes as well as special technologies to reduce the heat-affected zone.

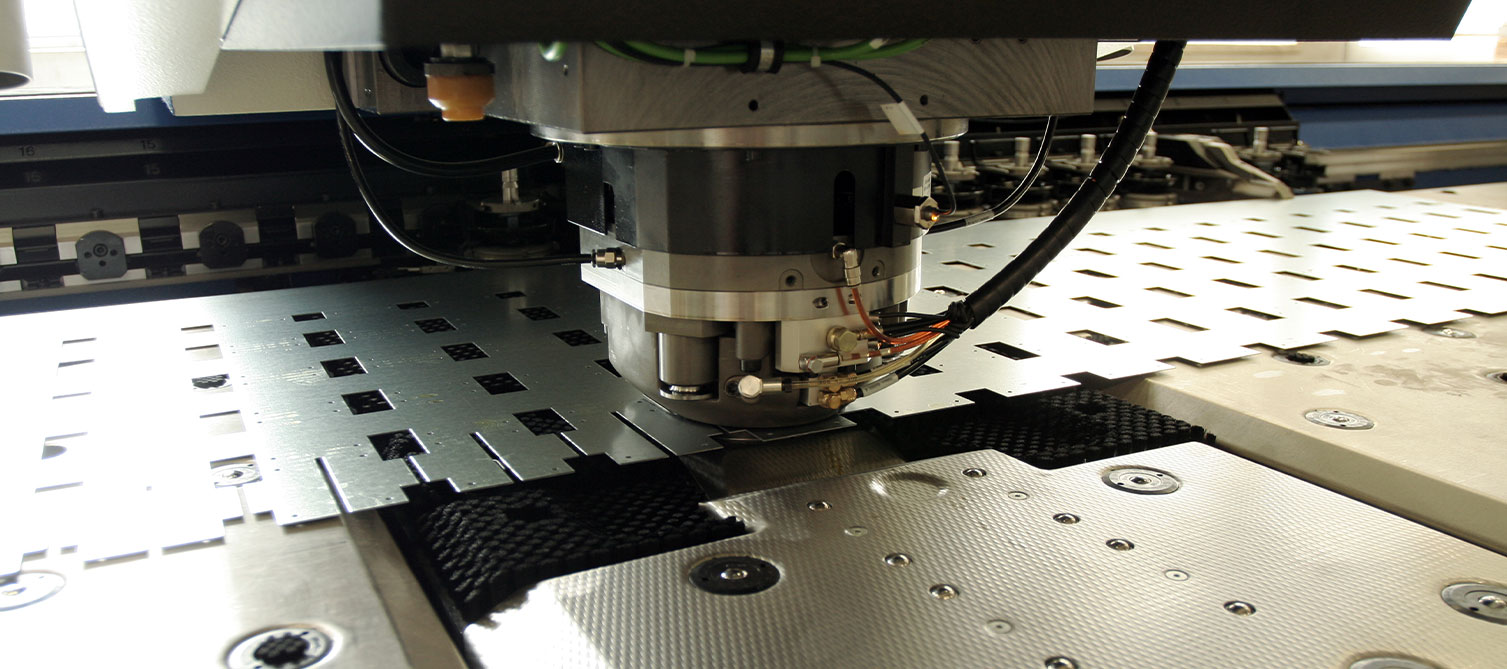

Industry requirements

Our machines are often used for the machining of highly stressed turbine parts made from special materials. Well-known turbine manufacturers and leading global airlines use our high speed milling and spark erosion technologies for both new production and turbine maintenance.

Special solutions

Our eroding technology for special materials, for example Inconel, is characterized by a very low formation of the heat-affected zone (white layer zone), which reduces the risk of microcracks in the material. Multi-axis eroding is our daily business here. We have solutions for "in-process"-measurement with data set and automatic RTCP calculation.

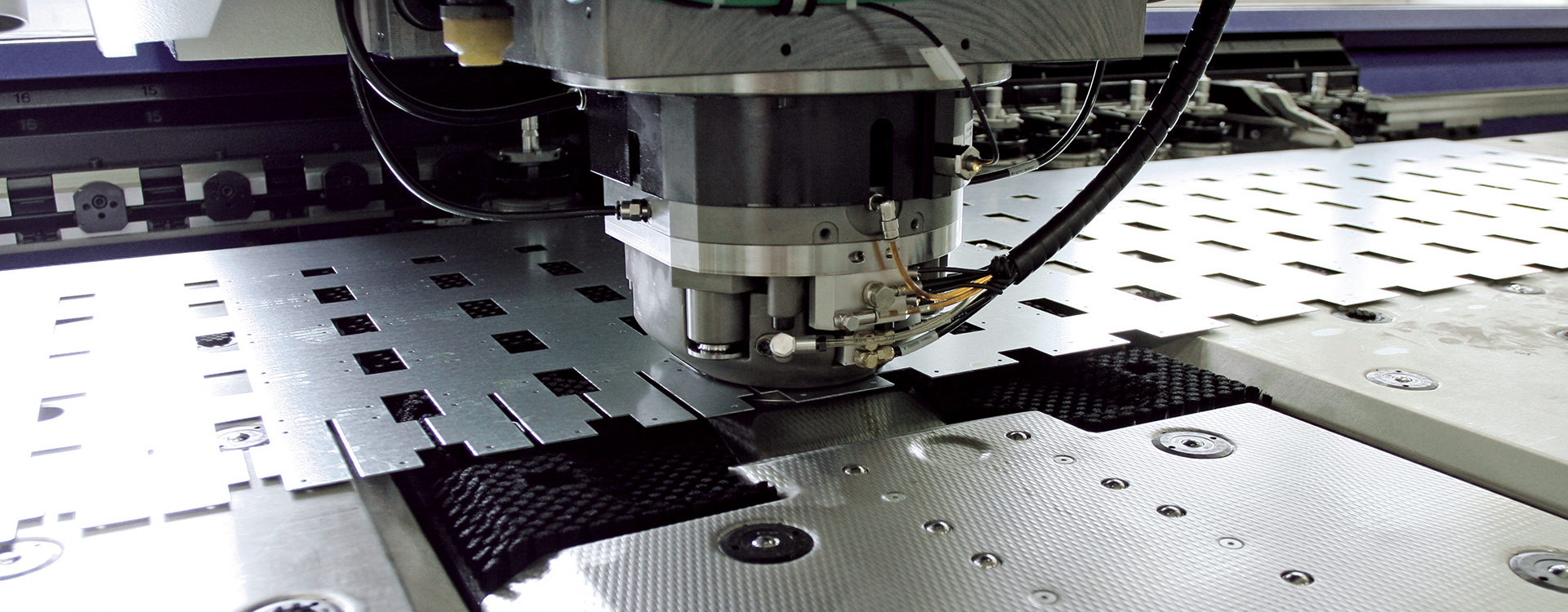

Industry requirements

The requirements of this business sector are often the machining of high-strength or extremely hard materials. EDM machining is mainly reduced for the machining of various hard metals or sintered materials. This requires special eroding technologies.

Our EDM machines are ideally suited for these demanding tasks.

Special solutions

We have special eroding technologies for different carbides. Special carbide packages make our EDM machines even more efficient.

Industry requirements

Due to the technological changes in vehicle construction (particularly caused by the expansion of the electromobility), reducing the weight of components is extremely important. The increased use of aluminum components produced in die-cast moulds are therefore a major issue.

Die-cast parts are becoming more complex and also larger. Giga-castings and gigantic die casting presses are used to produce die casting moulds of previously unknown sizes.

Special solutions

The technology combination offers considerable saving potentials.

Our sink EDM machines, from small to large, are all in Gantry-design. They therefore offer an excellent ratio between working area and axis-travel with a small footprint.

Thanks to large electrode changers, long runtimes can generally be realized even with stand-alone machines, without additional automation.

Furthermore, our PowerSPARK erosion technology reduces the susceptibility for microcracks in highly stressed die casting moulds. This is why we are the leading supplier and technology partner for die casting mould manufacturers.