Turbine machining

Complex geometries, handled with confidence

Maximum precision forHigh-

performance

turbines

The performance and efficiency of modern gas turbines, steam turbines, and aircraft engines depend largely on the precision of their components. Our electrical discharge machines (EDM) are specially optimized for machining high-strength materials such as nickel-based superalloys and titanium alloys.

Through the controlled use of EDM technology, we minimize the heat-affected zone (HAZ) and avoid structural changes.

The result: maximum dimensional accuracy, optimum surface quality, and durable turbine components for applications in aerospace, power generation, and the oil and gas industry.

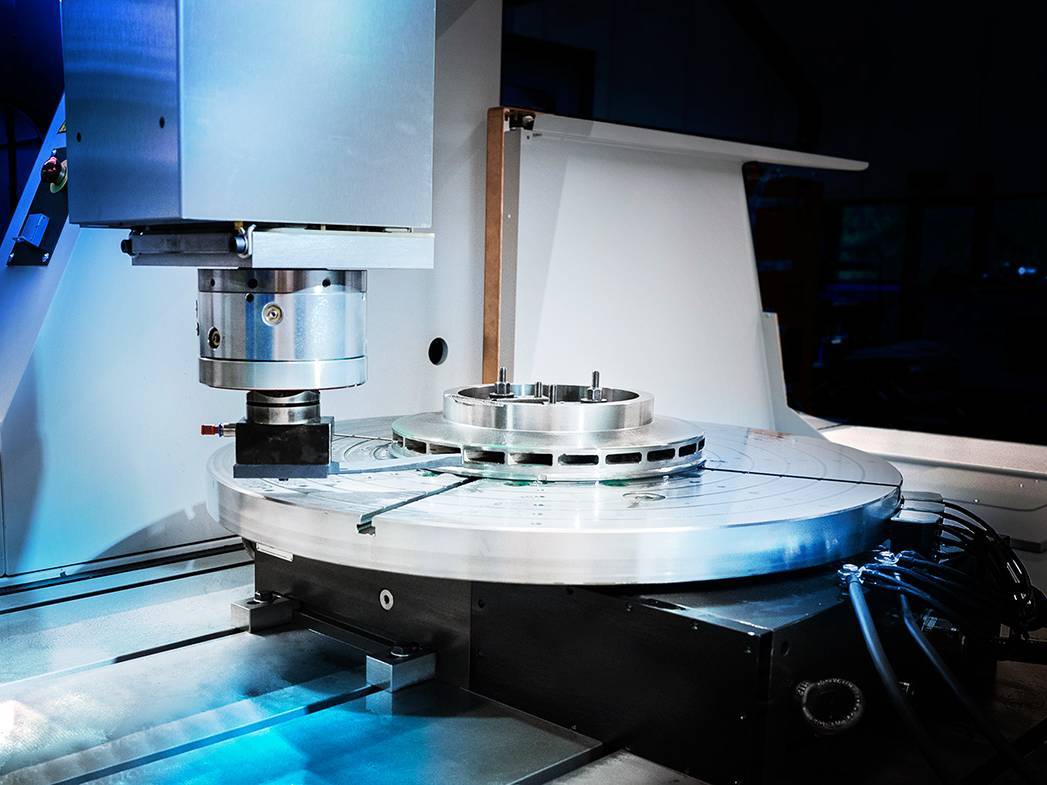

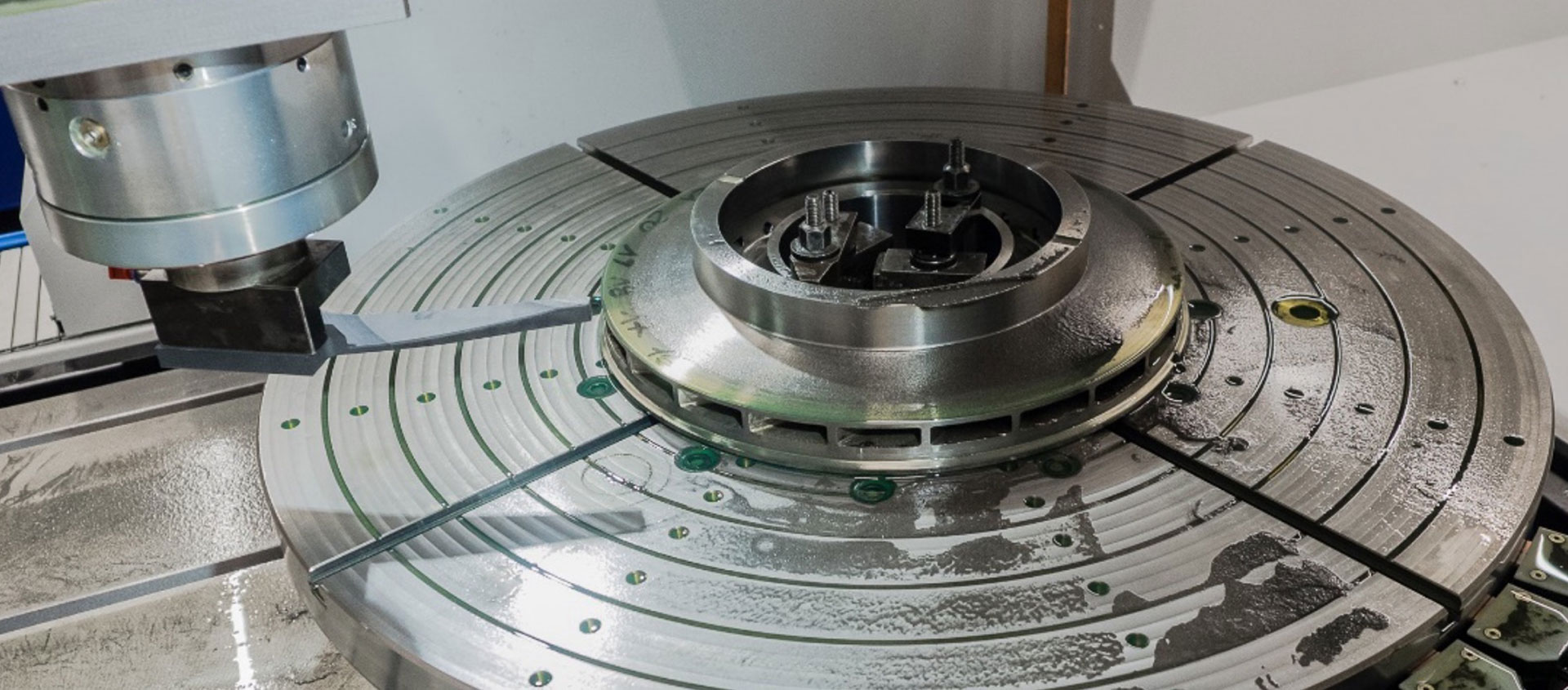

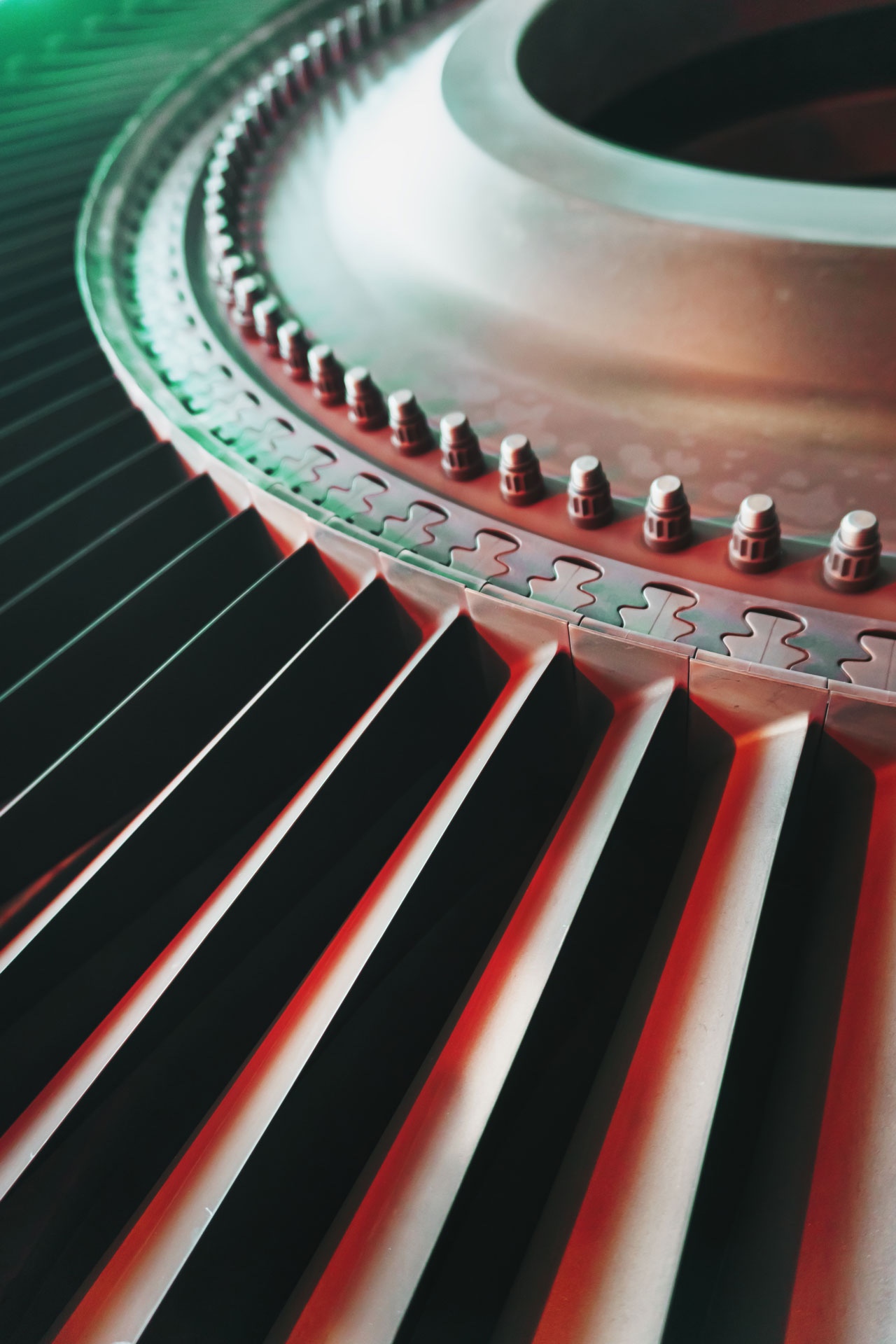

Turbine wheels, compressor wheels and impellers

Perfect geometries for maximum flow efficiency

The flow characteristics of turbine and compressor wheels are decisive for the performance of modern turbomachinery. Our EDM technology enables high-precision machining of finest structures with tightest tolerances — whether for compressor wheels in aircraft engines, turbine impellers in power plants, or high-performance impellers for offshore installations.

Special sink-EDM-strategies ensure perfect edge quality and prevent unwanted hardening in the heat-affected zone (HAZ) through controlled energy input. The result: longer service life, maximum performance, and highest energy efficiency.

Applications

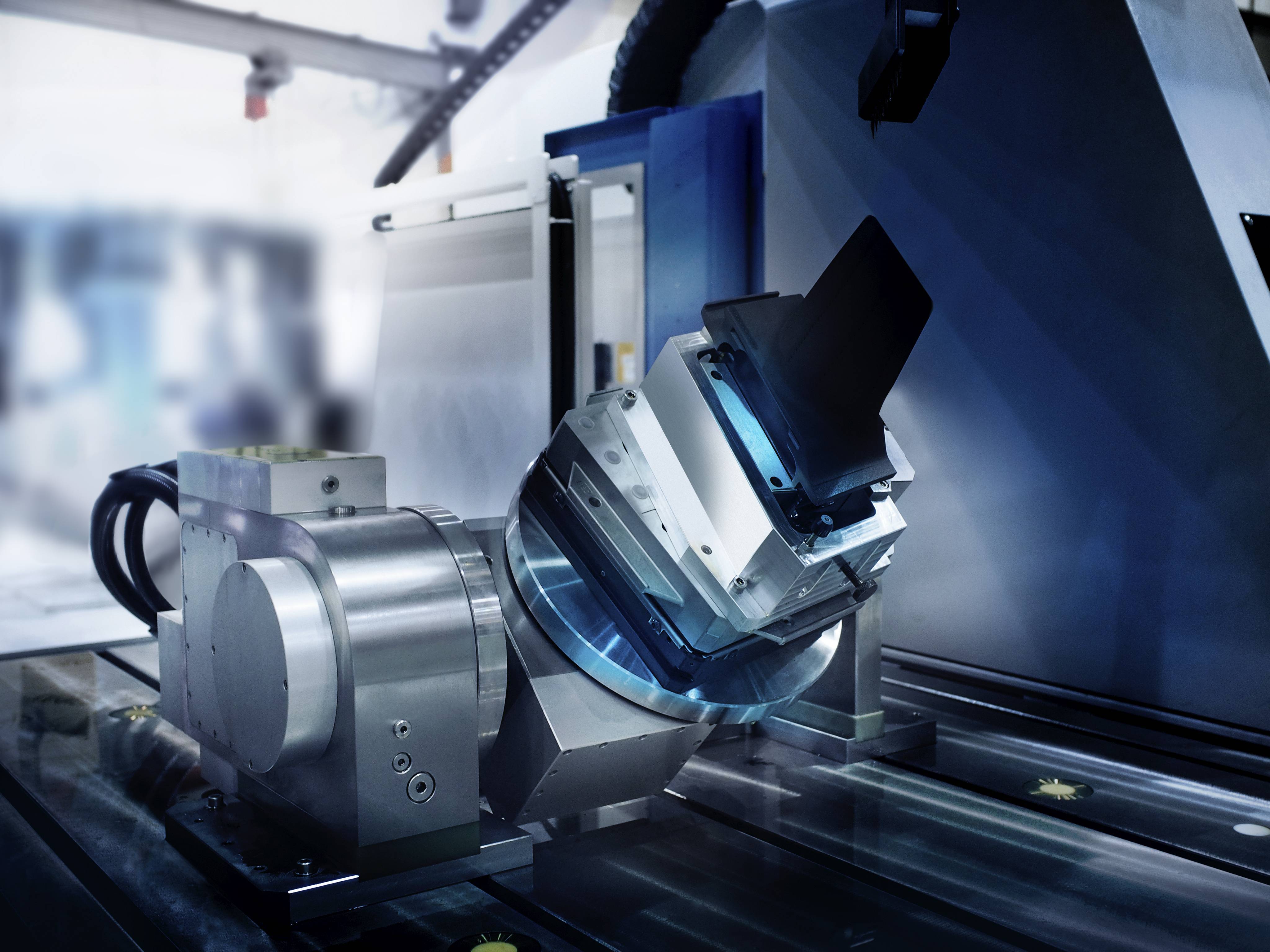

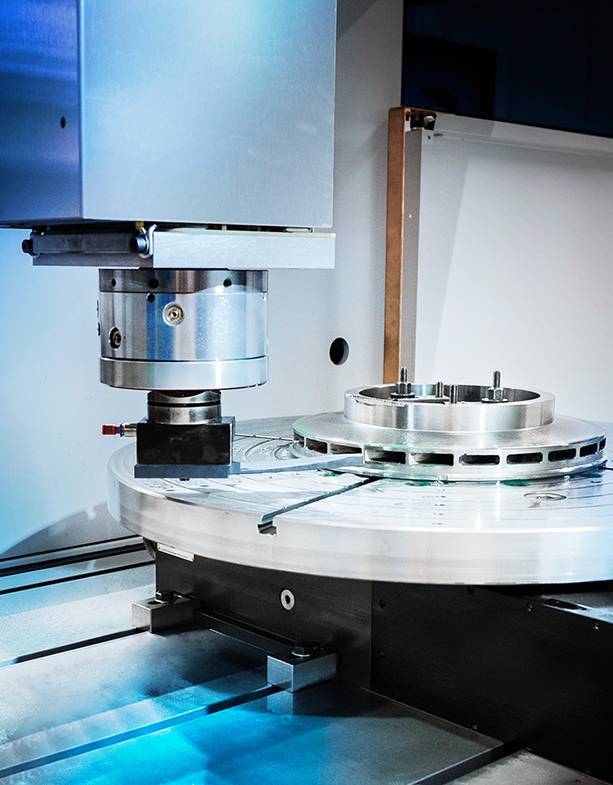

GANTRY EAGLE 1400 plus | 5-axis

Turbine wheel

Technical data

programmable/automatic

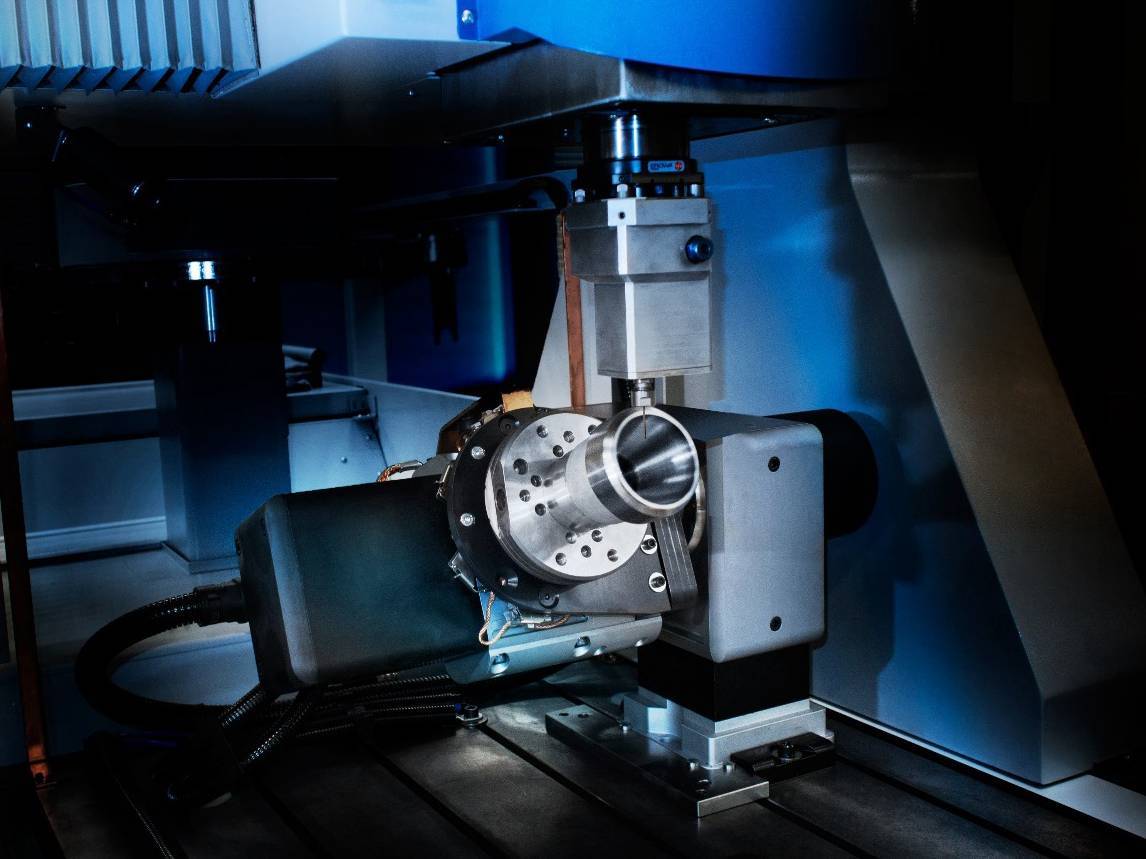

GANTRY EAGLE 1200 | 5-axis

Turbine blade

Technical data

programmable/automatic

EDM

Precision machining for maximum performance

EDM is an essential part of the manufacturing process for turbines and compressor impellers.

Turbine blades

High precision cooling structures for extreme demands

Turbine blades in high-pressure turbines must withstand enormous thermal and mechanical forces. OPS-INGERSOLL has perfected EDM technology to precisely, efficiently, and reproducibly machine micro cooling channels and aerodynamic profiles in high-temperature-resistant materials such as Inconel and titanium.

Our optimized processes enable precise control of the heat-affected zone (HAZ) to prevent hardening, cracking, and undesired structural changes. The result: heavy-duty, durable blades with maximum performance for highest efficiency in energy generation, aerospace, and the oil and gas industry.

All over the world

Trust in our technology

For almost 30 years, leading manufacturers and suppliers worldwide have relied on our 5- and 6-axis EDM machines for precise turbine machining. Whether in aerospace, power generation, or industry, our solutions stand for maximum precision, reliability, and innovation and are successfully used by companies around the globe.

We see ourselves not only as a machine supplier, but also as a partner for challenging technologies. We treat customer-specific know-how absolutely confidential.

For this reason, we have decided not to mention specific references. However, the international scope and variety of our customers clearly shows that our expertise in turbine machining has been highly valued for many years.